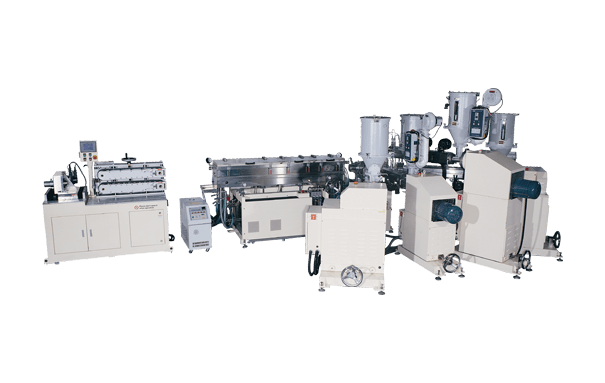

Multi-Layer PE Tube Co-Extrusion Line

FEATURES

BONMART supplies multi-layer PE tube co-extrusion lines for the flexible packaging industry, and up to 5-layer extruder technology provides processors with increased productivity and flexibility.

Plastic material has its own characteristics, we use and combine several kinds of materials in the co-extrusion system. Therefore, the characteristics of a single-layer tube can't compete with the complex characteristics of a multi-layer co-extrusion tube.

Plastic material has its own characteristics, we use and combine several kinds of materials in the co-extrusion system. Therefore, the characteristics of a single-layer tube can't compete with the complex characteristics of a multi-layer co-extrusion tube.

Glossy surface. (using: EVOH / RESIN / PE)

Extensive color combination. (using: PE + PEARL / PE + PIGMENT)

Excellent barrier property. (using: PE / TIE RESIN / EVOH / TIE RESIN / PE)

Scratch and dust free. (using: LDPE / LDPE / LLDPE)

Co-extrusion is used on pesticide container, toothpaste, side window, multicolor, long preservative cosmetic... etc.

MAIN SPECIFICATIONS

Screw dia (inner): 45 mm. L/D: 32/1

Screw dia (resin): 35mm. L/D: 30/1

Screw dia (EVOH): 30mm. L/D: 25/1

Screw dia (outer): 40mm. L/D: 32/1

Screw type: full flight

Motor: 15 HP x 1 pc, 10 HP x 1 pc, 5 HP x 2 pcs

Water consumption: ice water: 120 L/min. 5 ~ 10 °C

Air consumption: 10 L/min

Power consumption: 95.5 kw

Extrusion linear speed:

Medium speed: 10 m/min (Ø35 mm) (EDC-08-05)

High speed: 20 m/min (Ø35 mm) (EDC-16-05)

Medium speed: 10 m/min (Ø35 mm) (EDC-08-05)

High speed: 20 m/min (Ø35 mm) (EDC-16-05)

Cutting speed: 100 pcs/min

Tube dia range: Ø16 ~ 60 mm

Machine size: 7000 x 3500 x 2300 mm

Total net weight: approx. 5200 kg

Cutter PLC: Delta