Bonmart

FEATURES

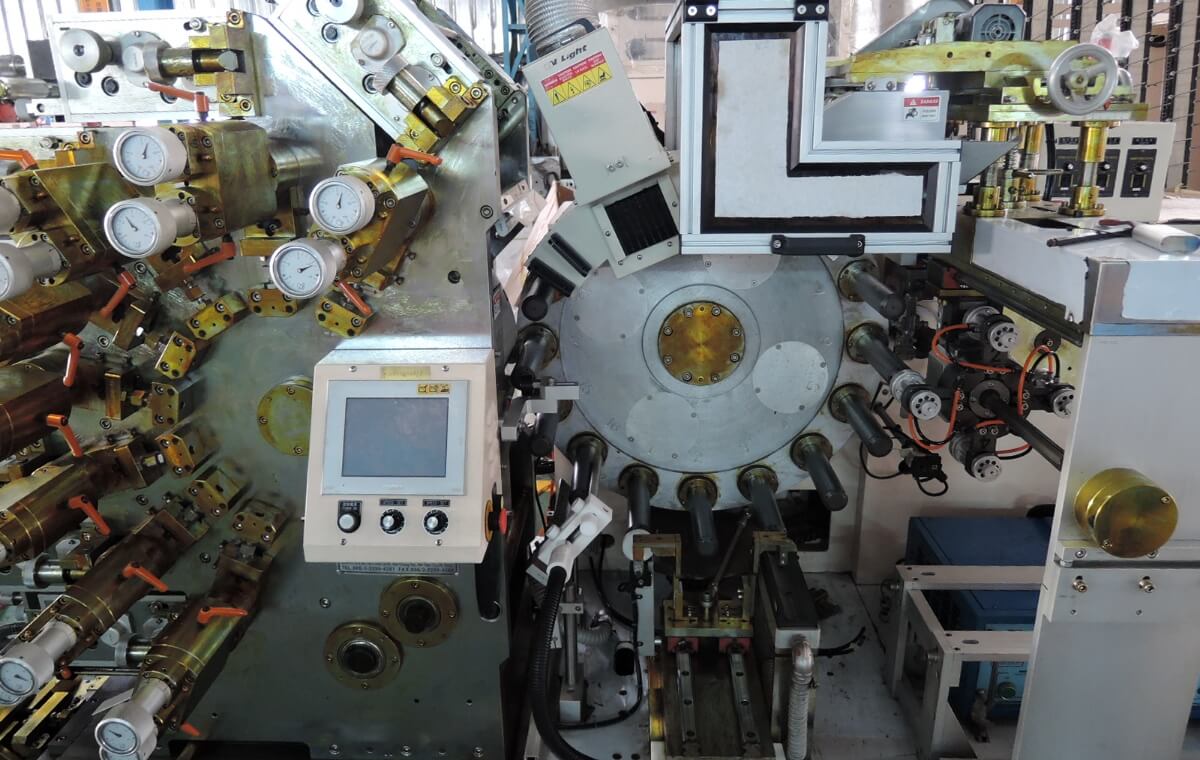

Equipped with a computer that stores up to 250 sets of production data and a monitor that displays real-time operating status.

Tubes are manually inserted and removed with the help of an air-blowing unit.

Features a double-head mold for high-speed production.

Supports integration with automatic tube loading machine and robotic hand to achieve automation

MAIN SPECIFICATIONS

Shuttle Injection Heading Machines

| Tube Dia Range | ø19–50 mm |

|---|---|

| Tube Length | 50–215 mm (Oval tube 70–215 mm) |

| Heading Speed | 20–40 pcs/min |

OTHER

Success Case