Products

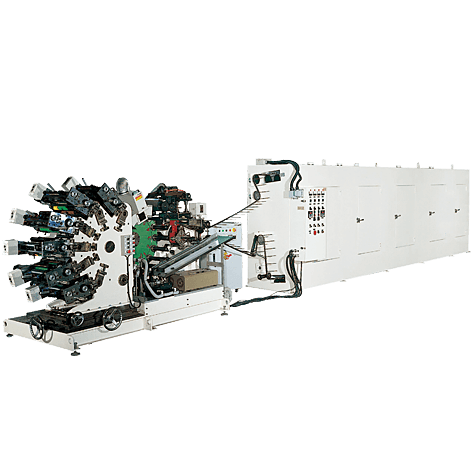

6 Color PE Tube Dry Offset Printing Coating Machine

-

-

FEATURES:

Precise index ensures accuracy of every movement. It is easy to disassemble the printing mandrel. Tube feeding system works with detector. Coating mechanism will not move. Without tubes on mandrels. Equipped with precipitator. Corona system can keep tube clean before printing. With optional sleeve printing mechanism. Tubes are headed directly after printing. No double-heading or double cutting procedures and save material. Vastly used on printing different shape of tubes.

For UV lacquer, special UV oven is required, which is equipped with rapid drying mechanism to produce tubes with glossier surface. We also offer UV & heater oven, which can save electricity and without space-limit. Customers can choose either of them accordingly.

Well-devised Ink-transmission system runs well, especially in broad area printing and screen printing. Foldable ink unit is easy to clean, change color and printing plate. -

MAIN SPECIFICATIONS:

Ink unit motor: 7.5 HP with encoder, inverter Mandrel unit motor: 3 HP Oven unit motor: 3 HP Ink adjust motor: 150 w x 6 pcs Printing ink: UV ink Printing plate: copper, zinc, polymer Corona capacity: 3 kw UV.dryer capacity: 5 kw, 180 w/cm2 Printing dia: Ø19~60 mm Printing length: 200mm (Max.) Printing speed: 60~80 pcs/min Air consumption: 150 L/min Power consumption: 55 kw Pin No.in oven: about 1100pcs. (10 meter oven) Machine size: 15000 x 1500 x 2000 mm Total net weight: approx. 6600 kg PLC: Mitsubishi

-