Products

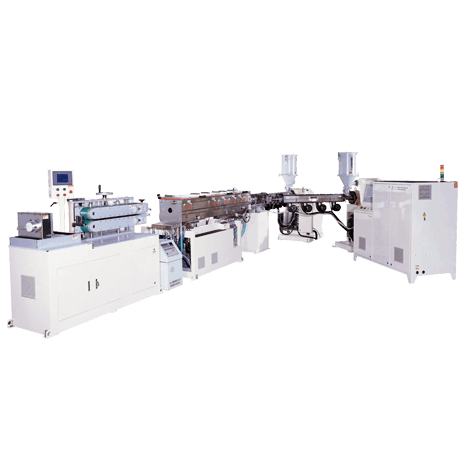

Two-Layer PE Tube Extruder & Cutting Machine

-

-

FEATURES:

Two-layer extrusion tube can reduce material cost. (using: Pearl + PE/PE + Pigment) The temperature controllers of different materials can be controlled individually. In this way, we can find out the best running condition on the materials both in running fluency and dissolubility. The surface of co-extrusion tubes made by two-layer machine is more glossy than the surface of mono-layer tubes. Using the same material on two-layer co-extrusion can increase the water-resistance and anti-penetration of the materials for about 20~30%. (using: PE + Pigment. inner: recycled material.) -

MAIN SPECIFICATIONS:

Screw dia (inner): Ø45 mm. 15 HP Screw dia (outer): Ø40 mm. 10 HP Screw L/D ratio (inner): 33/1 Screw L/D ratio (outer): 32/1 Screw type: full flight Water consumption: ice water: 120 L/min. 5 ~ 10 °C Air consumption: 10 L/min Power consumption: 66 kw Extrusion linear speed:

Medium speed: 10 m/min (Ø35 mm) (EDC-08-02)

High speed: 20 m/min (Ø35 mm) (EDC-16-02) Cutting speed: 100 pcs/min Tube dia range: Ø16 ~ 60 mm Machine size: 8000 x 3500 x 2000 mm Total net weight: approx. 3240 kg Cutter PLC: Delta

-