Products

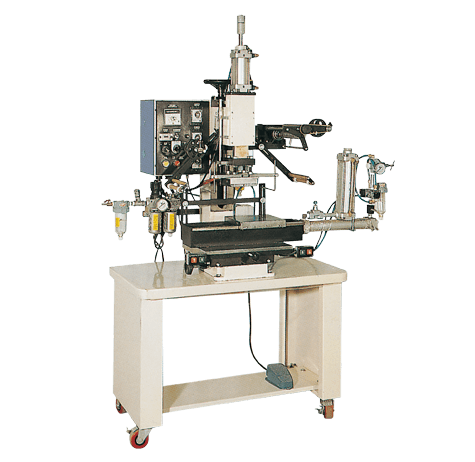

Plastic Hot Foil Stamping Machine for Tube

-

*Hot foil stamping: also known as hot stamping, is a printing technique that uses a heated die and foil to create a metallic or matte finish on different materials. The process involves applying heat and pressure to transfer the foil onto the surface of the material, creating a permanent and durable imprint. Hot foil stamping is widely used in various industries, including packaging, stationery, and apparel, to enhance the appearance and branding of products.

-

INTRODUCTION:

The HSM-10-M Model hot foil stamping machine is a state-of-the-art automatic hot foil stamping machine designed specifically for plastic tubes. It offers a range of advanced features and benefits, including high precision, quick setup, fast production, ease of use, and versatility. The HSM-10-M Model has had a significant impact on the hot foil stamping industry, particularly in the plastic tube segment, making it easier and more efficient to create high-quality printed designs on plastic tubes. -

OPERATION PROCESS:

The HSM-10-M Model hot foil stamping machine uses a fully automatic feeding and indexing system to transport the plastic tubes through the machine. The tubes are first loaded onto a magazine, which is then fed into the machine. The indexing system then positions the tube in the correct location for the hot foil stamping process. A heated die presses a foil onto the tube, transferring the design onto the surface. The machine then ejects the stamped tube and repeats the process for the next tube in the queue. -

MAIN SPECIFICATIONS:

- Stamping dia: Ø19~50 mm

- Stamping length: 3~120 mm

- Stamping speed: 5~10 pcs/min

- Heater: 1.5 kw

- Air consumption: 50 L/min

- Power consumption: 1.6 kw

- Machine size: 1250 x 600 x 1500 mm

- Total net weight: approx. 190 kg

-

BENEFITS:

The HSM-10-M Model hot foil stamping machine is a fully automatic hot foil stamping machine designed specifically for plastic tubes. It is equipped with advanced features that make it efficient, reliable, and easy to use. Here are some of the key features and benefits of the HSM-10-M Model:- Efficiency: The HSM-10-M Model is highly efficient, with a high production speed and quick setup time. This makes it ideal for high-volume production environments.

- Precision: The HSM-10-M Model uses a high-precision indexing system that ensures accurate and consistent positioning of the foil on the tube. This results in a high-quality print with no smudging or misalignment.

- Versatility: The HSM-10-M Model can be used to stamp various designs and patterns on plastic tubes, including logos, text, and graphics. It can also be used to stamp on different types of foil, including metallic, holographic, and matte.

- Ease of Use: The HSM-10-M Model is designed for ease of use. It has a user-friendly interface that allows operators to easily program and control the machine.

-